Powerful Root Cause Analysis: the Untainted Truth about the 5 Whys

Like most business leaders, I face a never-ending stream of decisions to make and problems to solve every single day. As such, root cause analysis needs to be rock-solid, and it is tempting to use techniques like the 5 Whys. The method is plain simple: when a problem occurs, you ask why five times to get to its root cause. The solution to the problem then becomes obvious, and you just have to implement it to prevent the issue from happening again. One famous illustration of the 5 Whys technique is the Titanic example. Something like:

- WHY did the Titanic sink?

- The Titanic hit an iceberg which tore part of the hull and water got in. WHY?

- The lookout saw the iceberg too late, and the helmsman couldn’t change course quick enough. WHY?

- The ship was sailing faster than its usual speed in such conditions. WHY?

- The captain had ordered to pick-up the pace to arrive one day ahead of schedule in New York. WHY?

- The Director of the White Star Line wanted to create sensationalist news and a surprise appearance in New York ahead of schedule!

Here we are! The primary root cause of the Titanic sinking (and more than 1,500 deaths) is the quest for fame from an indelicate director! … I trust you can see the power of the 5 Whys approach and how the apparent simplicity of the scheme can seduce. With the 5 Whys, you put aside sophisticated root cause analysis techniques and tackle any problem by just (annoyingly) repeating the WHY pattern 5 times, correct?

Well, not quite so! I’m neither a Lean nor a Six Sigma productivity expert. I’m just an executive who always faces typical business life challenges, and wants to find reasonable ways to address the most impactful issues. So, let me share the most obvious limitations of the 5 Whys technique I encountered, and a more robust approach I experimented with, that should increase your chances of adequately solving any problem.

The 5 Whys in the context of root cause analysis history

Not sure you know Sakichi Toyoda? You actually do! He was an inventor and industrialist who founded Toyota Industries. Toyoda also developed the concept of 5 Whys viewed as the basis of Toyota’s scientific approach. Toyota still leverages this approach to problem-solving and root cause analysis on the production floor, as it aligns well with its “Genchi Genbutsu” philosophy (“real location, real thing”). Put differently, if you want to truly understand a situation, observe, collect facts and data at the actual site where work takes place. The technique has reached other companies and organizations far beyond Toyota, and it’s now used within Kaizen, lean manufacturing, and Six Sigma.

The 5 Whys also became quite popular in the tech startup world a few years ago. There are even hilarious videos about its use (and abuse!). Just check the one on Vooza, a video comic strip about startups and the tech world! Like many of you, I used the 5 Whys technique in the past and stopped using it.

Understanding root causes is not as simple as asking one question and getting one answer. In my experience, the 5 Whys technique has been used more as a shortcut and came with limited real evidence. The reality is more complex, though, and interdependencies have to be taken into account. Each why needs to go with a series of questions that invite more details and provide a more in-depth understanding.

There’s hope though, and here are 5 steps (not Whys!), inspired by Six Sigma that I have used with decent success:

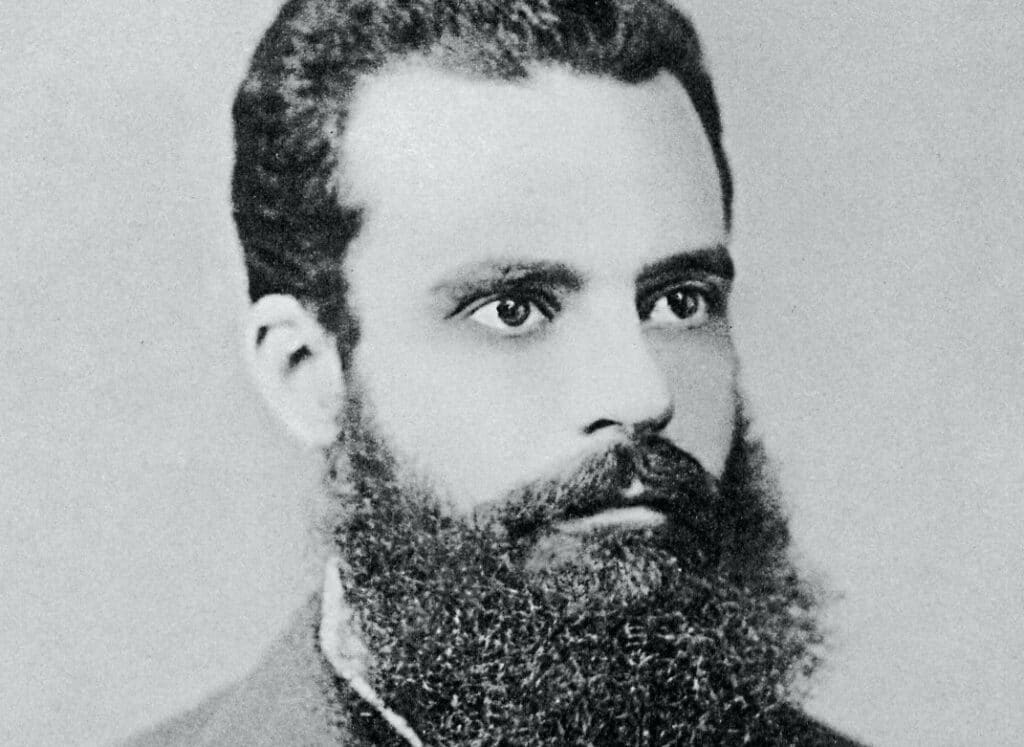

Step #1: Define and Prioritize Problems like Pareto

First, don’t try to solve all of the issues coming at you. Once again, the Pareto Principle (from prolific Vilfredo Pareto) is coming handy (80/20 rule). By focusing on solving your most impactful problems, you stand a better chance of making the difference. If you’re interested in digging further, I highlighted the Pareto Principle’s benefits in another post about five secrets for product success.

As you identify your problem, a powerful technique is to make sure you correctly state it. Coming to a problem statement is a collective sport. Very often, what is an issue for some isn’t even the slightest one for others. Yet, articulating the problem, taking multiple perspectives into account, will go a long way in ensuring alignment, and shared willingness to solve it!

Consider your key stakeholders and make sure the “resolution” team has a well-balanced representation of the company’s different functions that need to be involved. Also, make sure you establish proper roles. Who’s the “guardian of consistency”, who will lead the investigations, who will drive the analysis?

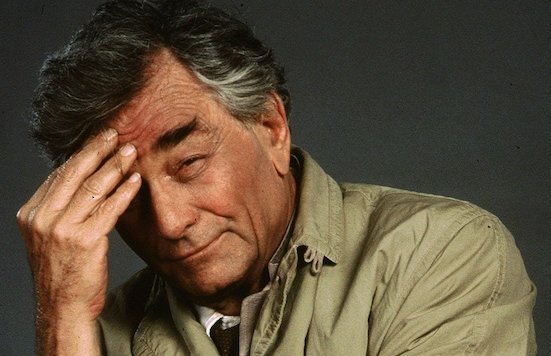

Step #2: Collect Data and Gather your Facts like Columbo

Have you ever watched the crime drama television series starring Peter Falk as Inspector Columbo? If so, you already know the best detectives practice empathy and do their homework. They try to understand the root causes by putting themselves in the shoes of the witnesses, victims (and even murderers!). So, step back and build a 360-degree view of the situation by applying Columbo’s best techniques.

Along these lines, please note that, although you need to know the WHY, you shouldn’t ask WHY. With “Why”, you ask for rationalization, but you also open a floodgate that can be reminiscent of a muscled police interrogation. Instead, formulate questions that lead to a more detailed description of what happened in a non-judgmental way. Ask questions like “Tell me about what happened“, and then let them tell the story as they see it! If they don’t go far enough, ask “Tell me more” or “Describe it to me“. Trust me, it works!

Take solid notes, and don’t try to reach any conclusion yet. It’s detective work, and you need to gather your facts first. The point here is to ask for descriptions and stories that will provide you with the most robust details.

Step #3: Deepen your Investigations like Stephen Hawking

You, too, can become a deep thinker. It starts with determining the factors that led to the problem. These are not your root causes yet. Here’s where the WHY technique can be adapted. Don’t try to limit only one answer to each question though. In reality, there are often multiple factors for ONE identified issue. In the example of the Titanic, it sank because it hit an iceberg. Wasn’t it supposed to be unsinkable? In theory, yes. But with open bulkheads at the exact location, the ice tore the hull, it didn’t help! On top of this, it appears a former fire had weakened the area even more. All these factors severely challenged the unsinkability of the Titanic.

Also, especially beware of the metrics and numbers people will throw at you: “Figures don’t lie, but liars figure!” This can have insidious effects, and activate very subjective views. Therefore, it’s critical to understand how a metric is calculated and if it properly contributes to the whole picture vs. operating in a vacuum.

It reminds me of a fascinating example I encountered not so long ago: Retailers would give us low scores on shipments. Yet our OTS rates (On-Time-Shipment) calculated by operations were close to 99% (an excellent score). But we missed one crucial detail: we would only enter orders in the system when we knew for sure we would ship. Unshippable orders were canceled, leading to the false sentiment we were spot-on in our delivery. Still, no metric would capture the lost opportunities… Just an example!

So, you’ve gathered your facts and documented your issues like a champion. Is it enough for you to declare victory on your root-cause analysis? Not yet.

Step #4: Practice Root Cause Analysis like a Doctor

You now likely have a long list of facts, data, and indicators. It is time to analyze these and make sure you accurately differentiate between the causes and the symptoms. You know the saying: “Symptoms are misleading, causes are hidden”. A lot has been written about causes vs. symptoms or signs, so, like in the medical world, make sure you properly qualify the identified issues. Just think of a typical food poisoning example and the identified problems that come with it:

- Fever is a symptom, i.e., the manifestation of an underlying cause.

- The direct cause might be an infected meal you ate the day before.

- The root cause is a gap in the sanitation process at the farm of origin.

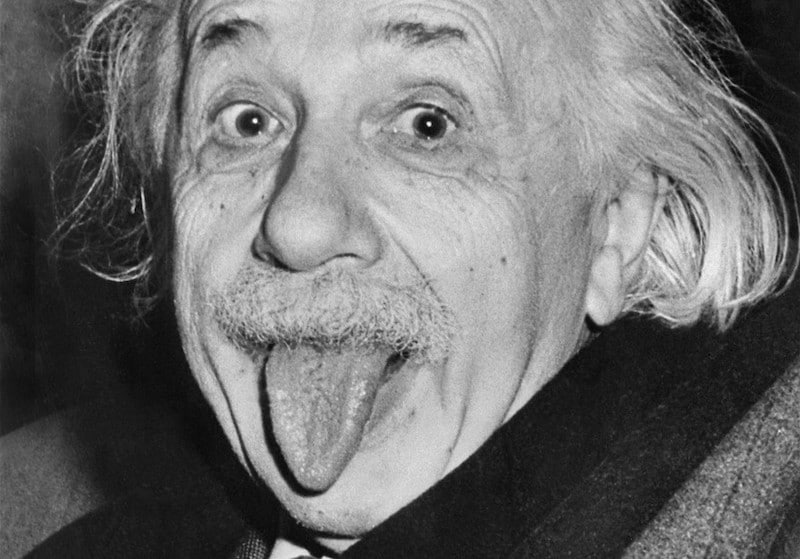

Step #5: Formulate Corrective Actions like Albert Einstein

Once you have your root-causes well-identified, be careful trying to solve them with just your management or functional teams. A fresh perspective will tremendously help, so make sure you bring the right experts in the room. It’s also time to get creative! Problem-solving is about switching gear and moving away from existing patterns (they likely created the problem you face in the first place). I’ve experienced that it might be best to dissolve the “resolution” team at that stage, and add fresh talent and minds. As Einstein said:

“We cannot solve our problems with the same thinking we used when we created them.”

Some could argue that you need such an outside perspective in the gathering and analysis phases too. Probably, but my take is that you can do most investigative and analysis work with your internal talent. Just ensure you can maintain enough objectivity and put “egos” on the side. If you can’t, get some external expert help.

Go and formulate your solutions, test drive them. As importantly, always build scenarios to assess the consequences of a potential decision. “What if…?” is a powerful tool for you to assess such hypothetical situations. This will help you settle on a solution to your problem that’s realistic and with clearly understood consequences.

In conclusion

There are other essential steps required to successfully implement the solution to your identified problem. You will likely need to educate and train the participating teams or individuals, and document your new processes adequately. But that’s a story for another day! Just make sure you find all the right ways for your teams to OWN the solution and drive it home.

Proper root cause analysis takes some practice, but it doesn’t have to be overly complicated. Just beware of ultra-simplification schemes, put your investigative hat on, and make sure you involve the right talent at the right time!

I’m genuinely interested in getting your feedback on this topic! How successful have you been in doing your own root cause analysis? Which other considerations worked for you? Just comment on this blog or drop me a note.

Also, if you want to fast-track your own problem-solving skills, The Product Sherpa is here to help you. We offer makeover programs for you to practice your critical thinking and get results. Our programs can be fully customized, and typically cover business essentials (business vision, product portfolio management, strategic pricing, turnaround situations…). Check them out here.